Sluice Room Total Soluiton

BIODECH&DDC

Redefining Infection Control

Innovation in the Sluice Room, Protect healthcare professionals and patients

while delivering optimal outcomes through infection control and waste management solutions.

DDC Dolphin’s design, innovation and manufacturing excellence has been

at the heart of global infection control strategies for over 30 years.

at the heart of global infection control strategies for over 30 years.

1. DDC Dolphin protects the safety of healthcare professionals and patients by

designing, manufacturing, and supplying sluice room equipment and

other infection control solutions.

BIODECH provides optimized DDC Dolphin solutions tailored to the domestic market,

delivering the best results for users.

2. Bedpan washer disinfectors reduce infection risks by cleaning and disinfecting

the toilet seat, minimizing exposure to harmful bacteria through waste.

3. Medical pulp (Bedpan) grinders crush disposable pulp containers and waste,

preventing healthcare-associated infections (HCAIs) and enabling cost-effective

and efficient facility management.

designing, manufacturing, and supplying sluice room equipment and

other infection control solutions.

BIODECH provides optimized DDC Dolphin solutions tailored to the domestic market,

delivering the best results for users.

2. Bedpan washer disinfectors reduce infection risks by cleaning and disinfecting

the toilet seat, minimizing exposure to harmful bacteria through waste.

3. Medical pulp (Bedpan) grinders crush disposable pulp containers and waste,

preventing healthcare-associated infections (HCAIs) and enabling cost-effective

and efficient facility management.

What is a Sluice Room

PART 1. Bedpan Washer Disinfectors

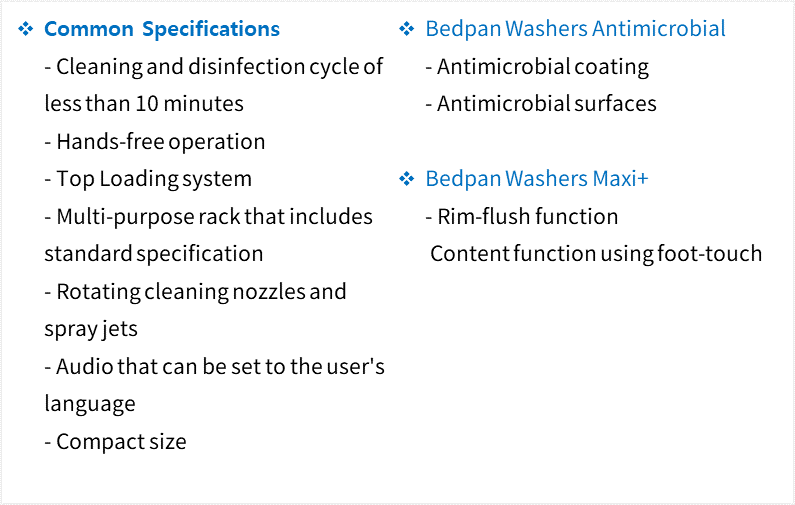

The PANAMATIC product line is designed to wash and disinfect bedpans,

commode pans, urinals, and other similar items made from various materials

such as plastic or stainless steel.

Purpose

To wash and disinfect patient bedpans made of plastic or stainless steel.

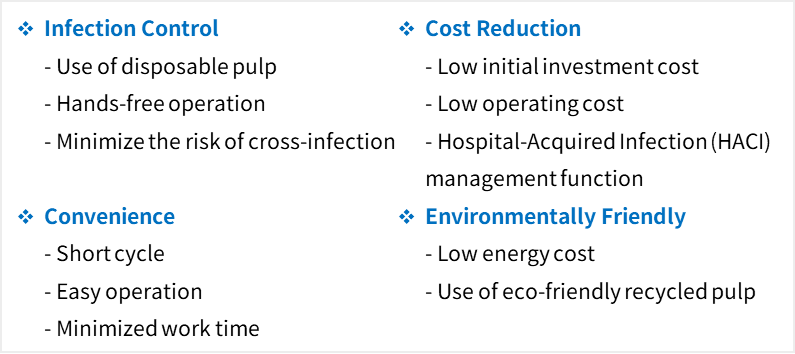

Features

Antibacterial material with silver ions (Ag+), operated by a sensor system (hands-free).

Standards

Maintains a temperature of 80°C to 85°C for at least 60 seconds

according to HTM2030 and ISO15883 standards.

PART 2. Medical pulp Macerators

PULPMATIC

PULPMATIC

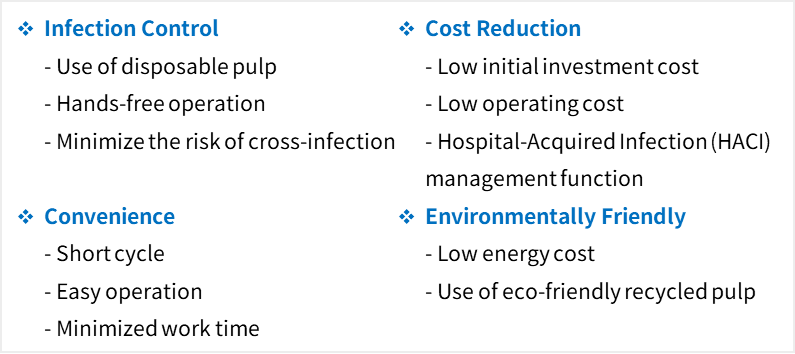

The PULPMATIC product line processes pulp most safely and effectively through

hands-free operation and antibacterial surface treatment technology to

minimize the risk of cross-infection.

Purpose

Pulverization of medical pulp and incontinence pads, and reduction of cross-infection

Features

Application of Weir technology and operation by sensor method (Hands free)

Weir system

Compared to the existing Hooper system, which allows objects with a diameter

of 50mm to pass through, A system where only pulp pieces smaller than 4mm are

discharged through the pipes

The PULPMATIC product line processes pulp most safely and effectively through

hands-free operation and antibacterial surface treatment technology to

minimize the risk of cross-infection.

Purpose

Pulverization of medical pulp and incontinence pads, and reduction of cross-infection

Features

Application of Weir technology and operation by sensor method (Hands free)

Weir system

Compared to the existing Hooper system, which allows objects with a diameter

of 50mm to pass through, A system where only pulp pieces smaller than 4mm are

discharged through the pipes